Summary: Customer satisfaction, profitability, and speed-to-market are at the core of business survival and growth. Organizations combine people, data, and processes, to create value for customers, enhance revenues and retain their competitive edge. Digital Engineering (DE) brings innovation to the design and functioning of both products & systems, resulting in better business models and a boost in overall growth and productivity. Here’s a comprehensive view of the DE process, practices, and strategy.

Modern engineers design complex infrastructure with too many variables to accurately account for – even with advanced engineering software. These designs require accurate modeling of real-world infrastructure through real-time data acquired from IoT devices. We call it Digital Engineering (DE), wherein engineers can accurately model design decisions based on real-world data to optimize products and infrastructure. Here’s an insight into all about DE.

What is Digital Engineering?

Digital Engineering is the synergistic use of electronic and software technologies to design, simulate, create, and test sophisticated software-intensive systems-of-systems – effectively designing, developing, testing and iterating applications using digital technology. The gamut of digital engineering services & solutions includes content creators, data analytics, machine learning, artificial intelligence, digital automation, and digital twin technology.

Ultimately, digital engineering aims to produce digital twins – the digital representations of actual and potential physical assets. It includes inanimate and animated physical assets: software, hardware, and the organic form. When we specifically talk about design, integration, and testing for Systems, the three forms are quite intertwined & equivalent.

What are the Business Benefits of Digital Engineering?

Digital Engineering, when used at the very beginning of a project, not only promotes better design but also aids in identifying and removing potential risks. This increases the predictability of building performance, price, and schedule.

Specific benefits:

- Innovation by locating, developing, and quickly validating concepts, observations, and analytics. Virtually reflecting qualities accurately can boost innovation, spot the gaps and thus reduce risks. A creative culture allows for low-risk testing of new solutions.

- Thanks to a digital twin’s improved testing capabilities, a corporation can test and predict project outcomes, better understand asset construction, and reduce risks. Speed, cost-efficiency, and realistic visualization of all possibilities support testing for any impactful scenario.

- Decisions become accelerated & data-driven with the element of traceability across the systems architecture. Embedded cybersecurity and assured compliance are an added advantage.

- Holistically, organizations benefit from better performances, greater flexibility, systematic management of complexities, and an overall return on investment.

Digital Engineering Strategy and Implementation

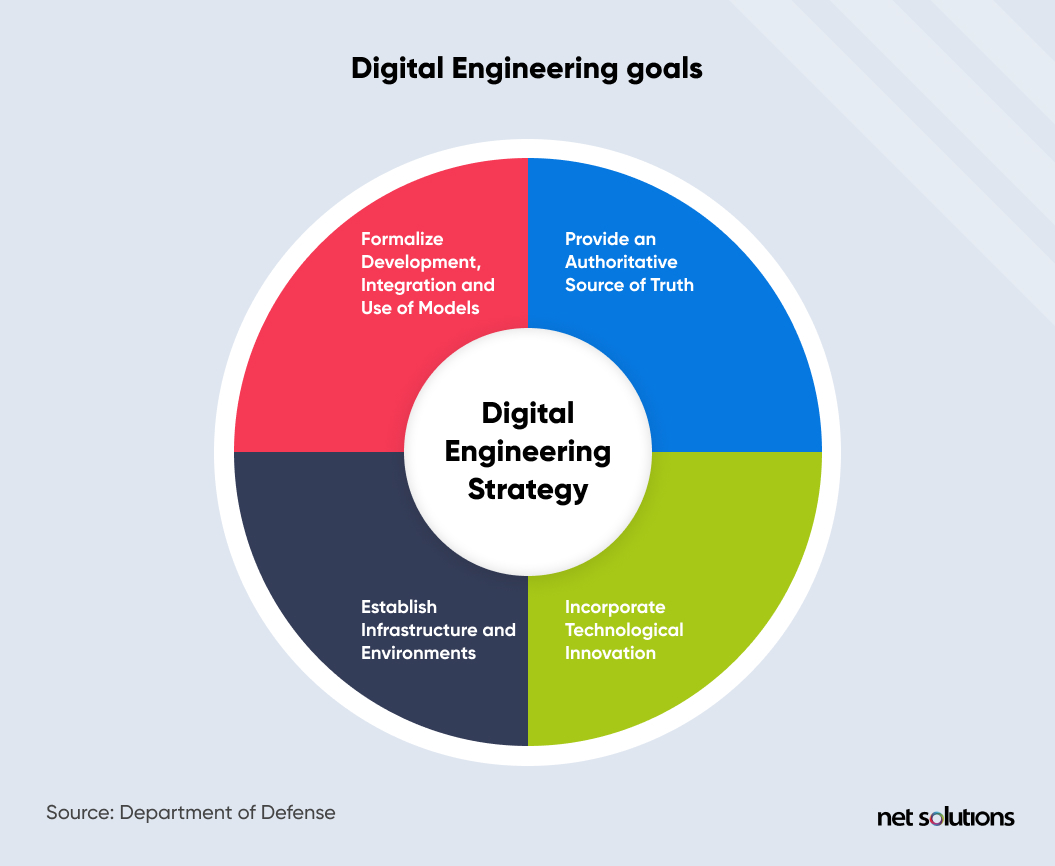

The U.S. Department of Defense (DoD), which unveiled its Digital Engineering Strategy in 2018, has been the most significant force behind the development and broad adoption of Digital Engineering.

The existing bureaucratic strategy placed a premium on exacting completeness and reducing risk. Thus, the Department saw the need for change to a performance-based culture where accountability and results are essential. DoD’s Digital Engineering Strategy and Implementation can guide companies across industries wanting to leverage digital engineering in their field.

As stated in the document released by the DoD, the five strategic goals of the DE strategy are:

1. Formalize the Process of Creating, Applying, and Using Models in Enterprise Decision-Making.

Formalizing processes related to digital engineering models allows for reproducible results. Start by creating a formal plan for supporting engineering decisions and activities throughout the lifecycle. Then, develop, integrate, and curate your digital engineering models. With these formalized processes, you can utilize models to assist with engineering tasks and decision-making throughout project life cycles with repeatable results.

2. Establish a Reliable, Authoritative, and Enduring Source of Truth.

Maintaining a source of truth is essential to success in digital engineering. It must be reliable, authoritative, and enduring to portray data in a model accurately. So, here’s a quick rundown on how you can establish an effective source of truth:

- Create a plan for the authoritative source of truth.

- Govern the supreme authority in truth.

- Utilize a reliable source of truth throughout the lifecycle.

3. Improve Engineering Practices by Incorporating New Technology.

Keeping your digital engineering practices up to date requires an effective process for incorporating new technology. Start by assessing current data streams sent to your digital engineering models and look for gaps in your data. Then, look for solutions to update existing technology to expand your data and enhance your digital engineering process.

4. Create a Supporting Infrastructure and Environment.

Digital engineering works well with the requisite IT infrastructure-managed services and environments. This includes expanding IoT devices to upgrading networking for a more robust connection between IoT devices and digital engineering models. Also, keep IT security a top priority when developing IT infrastructure and environments.

5. Enhance the Culture and Workforce to Embrace and Support Digital Engineering Throughout Project Lifecycles.

Your workplace culture must embrace digital engineering to find success. Start with expanding cross-department knowledge on how digital engineering can benefit your organization. Then, lead support efforts to transform aspects of your organization that can utilize digital engineering. Finally, offer continuous training for your workforce.

Digital Engineering Framework

Since the inception of the DoD strategy in 2018, several releases have added additional capabilities and updated the core documents based on the experiences in the pilot projects. The DE Framework initiated as ‘Stage 2’ of the development process in 2020 aims to work with new projects with an increasingly digital way of working.

The Systems Engineering Research Center (SERC), under the aegis of the DoD, created a Digital Engineering Competency Framework. The DECF gave clear workforce acquisition guidelines and marked the DE process training resources.

Below is another way of looking at the five objectives in the framework:

Adopting the framework brings in a consistent approach to DigitalDiital Engineering, simplifying the entire process for organizations.

Best Practices of Digital Engineering

Emerging technologies enhance project outcomes and produce innovative data and information. To keep up with such changes, here are some best practices to adopt:

- Establishing Agile Development Practices: Competitiveness depends heavily on flexibility and agility. Agile methods like scrum teams, iterative development, CI/CD, user interaction early in the development cycle, and productivity management facilitate a quicker time to revenue in this respect.

- Ensuring Comprehension and Command of the already available technology: Enterprises cannot get everything they need from one provider for their digital transformation. Thus, businesses must choose and integrate various distinct technologies, and success depends on comprehending these offers and using qualified staff.

- Implementing Modular Architecture: Composability and microservices are essential to innovative applications. APIs that access and exploit other systems and micro-services are said to be composable. The modular design has fine-grained, loosely linked components that use simple protocols.

The Many Arms of Digital Twins

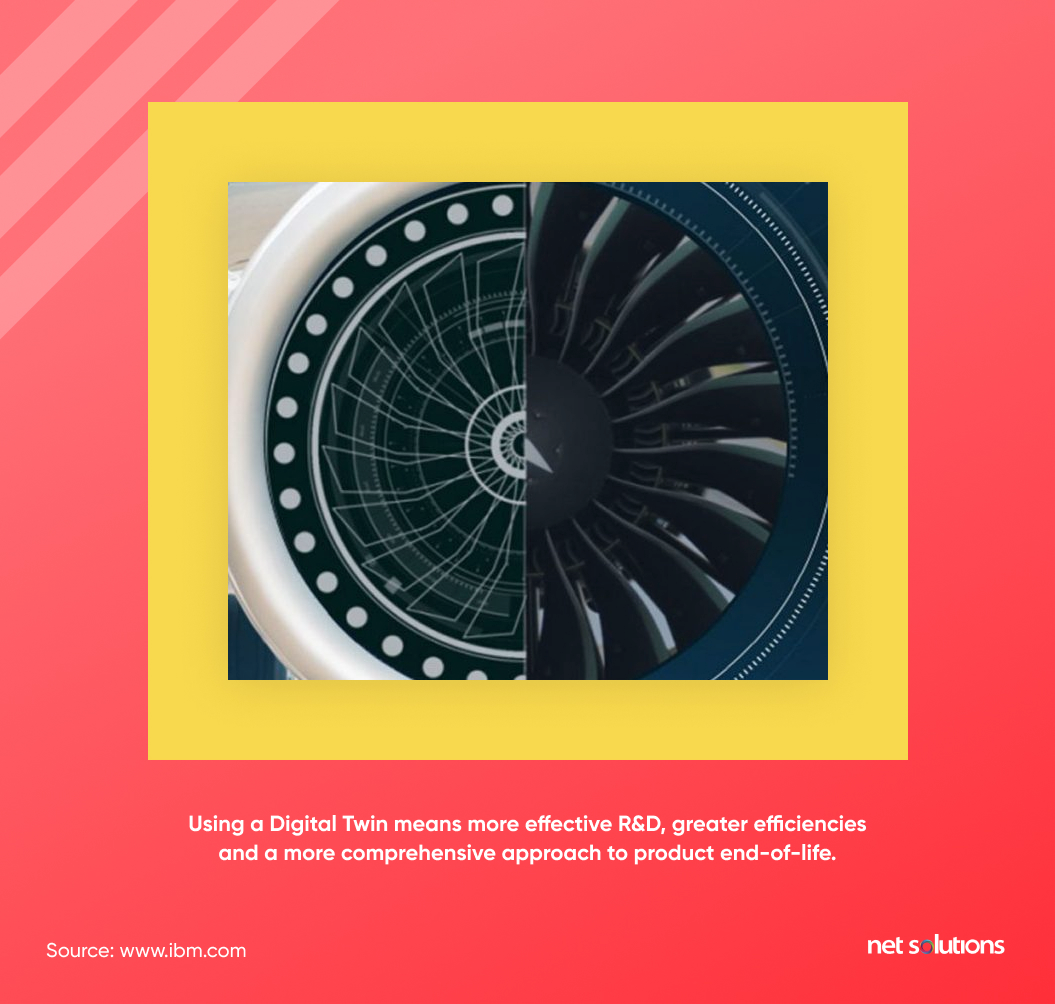

Digital twins connect the virtual and physical worlds. They are virtual models (replicas) of tangible physical objects, processes, or even systems. We create a complex virtual model as a replica of (twin) of a physical ‘thing,’ which could be a vehicle, a building, or a structure. Sensors are connected to the physical asset to collect data, which gets mapped onto the virtual model. You look at the digital twin – and you’d understand how the physical thing works in the real world.

Gartner defines digital twins:

A digital twin is a digital representation of a real-world entity or system. The implementation of a digital twin is an encapsulated software object or model that mirrors a unique physical object, process, organization, person, or other abstraction.

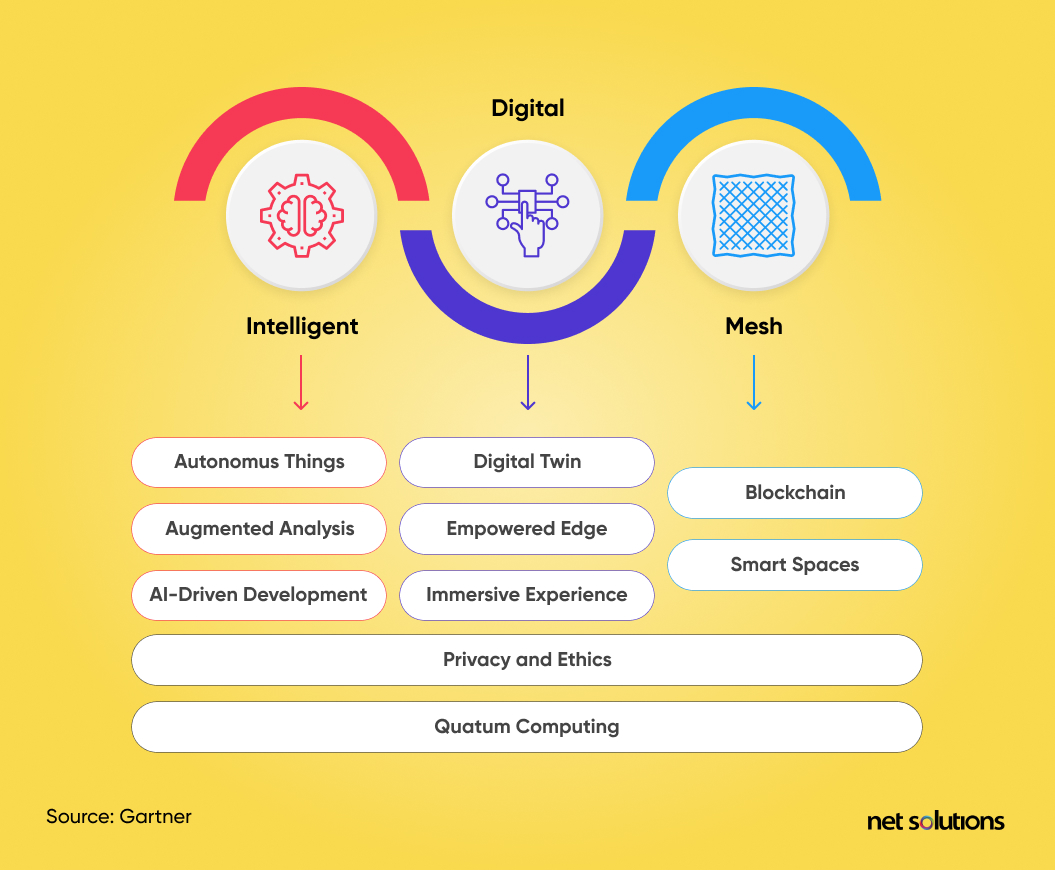

Created by synergistically combining Digital Engineering technologies with physical and virtual logical systems, they act as an organization’s competitive edge to develop, predict, operate and plan practically for the real world. Gartner lists the following top strategic technology trends, with Digital Twins figuring at the top of the segment:

In a world of complex & dynamic business environments, contingencies must be foreseen, tested, planned for, and addressed strategically. Digital twins link, analyze and enable visualization of all data points in an asset lifecycle. They aid innovative, agile, and progressive workflows with a bird’s eye view of past-present-future processes. Integrating AI into the system further brings digital twin chains seamless integration.

An object is studied for areas of functionality, and data is then run to a processing system and applied to the digital copies. Then virtual modeling helps run simulations, identify the gaps, and develop improvements. The result is invaluable insights that an organization can then apply to the original physical object.

This technological revolution in the design & architecture of systems implies an increasing value of the below-mentioned sub-disciplines:

1. Agile MBSE

Agile MBSE technologies scale and simulate Digital Twins recursively. Agile MBSE technologies synthesize a quarter-century of lessons learned from MDD, MBSE, and Agile/Lean Development technologies. They can provide the recursive architecture and design patterns needed to meet the fractal Digital Twin System-of-System conundrum.

2. Massive Mathematical & Dynamic ModSim

Massive Mathematical & Dynamic ModSim technologies get used for simulating Physical Twins as Digital Twins recursively. In this regard, mathematical (parametric) and dynamic (behavioral) simulations for Digital Twins must be widely used.

3. Artificial Intelligence (AI) and Machine Learning (ML)

Artificial intelligence & Machine Learning are revolutionizing how software-intensive Systems-of-Systems interact with humans; hence, they will play a key part in the Digital Twin evolution.

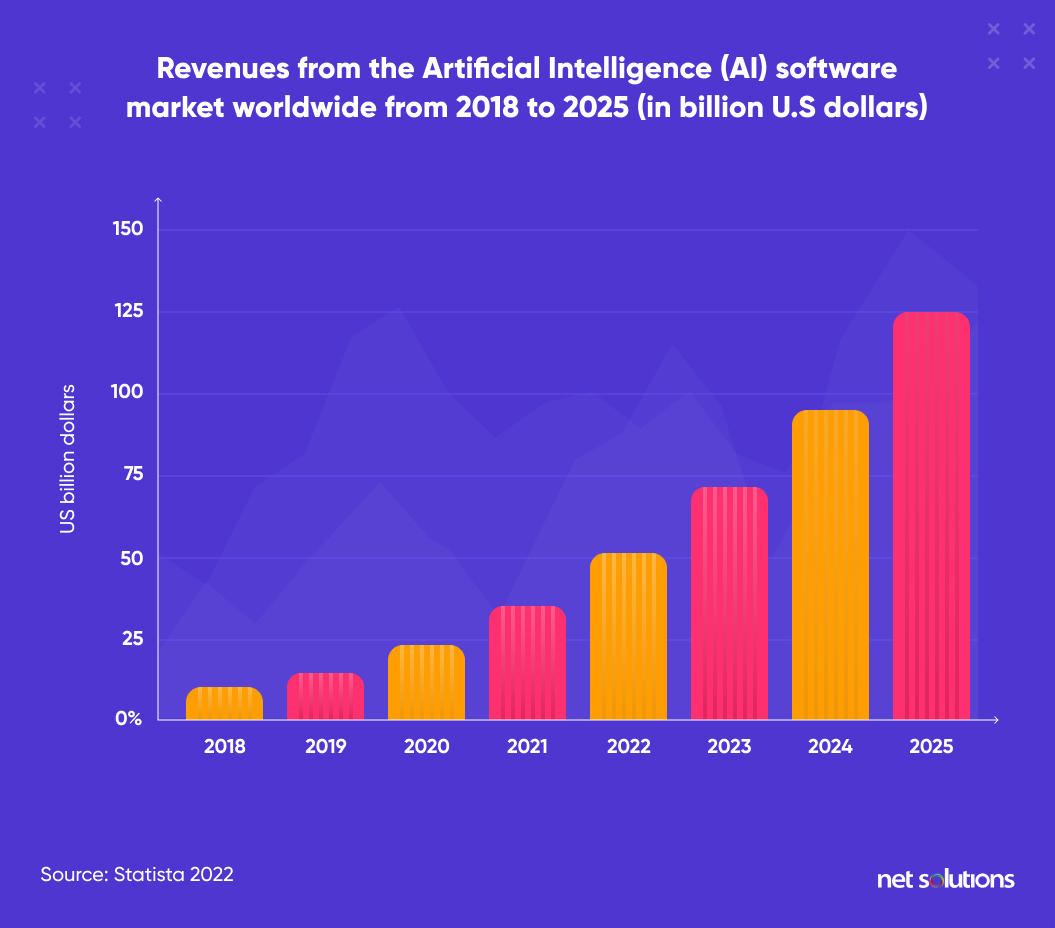

As per Statista, the global artificial intelligence (AI) software market is forecast to grow rapidly in the coming years, reaching around 126 billion U.S. dollars by 2025. The overall AI market includes natural language processing, robotic process automation, and machine learning applications.

The concept of ML also throws light on Machine Learning Operations (MLOps). MLOps streamlines the process of deploying and maintaining machine learning models in production. With MLOps, we work at avoiding “technical debt” in machine learning applications.

4. 3D CAD and 3D Printing

The electro-mechanical framework for the actual production of Physical Twins—and consequently, their Digital Twin counterparts—is provided by 3D CAD and 3D Printing (also known as Additive Manufacturing) technologies.

5. Virtual Reality (VR) and Augmented Reality (AR)

Virtual Reality (VR) and Augmented Reality (AR) provide the simulation infrastructure for Digital Twins’ enormous simulations (Simulation-of-Simulations). VR/AR technologies are revolutionizing how people engage with Systems-of-Systems; therefore, they will likewise shape Digital Twin technology.

Applications of Digital Engineering

For a company to prepare for the future, digital engineering will be crucial in all production industries, and some sectors are already setting the pace. Some applications of digital engineering in various fields:

1. Automotive Industry

The automotive sector is experimenting with digital product development and digital engineering.

Major automotive firms rely on digital engineering and Smart Factories to make prototyping more productive and less expensive. By digitizing this process, engineers can quickly run accurate tests on new technologies and bring them to market faster.

2. Process Industry

The process industry uses technical, chemical, and physical processes to extract and treat raw resources. It produces food and pharmaceuticals; thus, it has complicated production facilities and strict quality standards.

Process industries are currently using digital twins to compare a physical plant’s performance to a simulated plant, and IoT data feeds the plant twin to represent the physical plant accurately. With actual data, engineers can adjust parameters in the simulated plant to optimize processes and then test those changes in the physical plant.

3. Plant Engineering

Digital engineering is essential in plant design since development and testing are time- and cost-intensive. The mechanical and plant engineering sector is also under a digital transformation firestorm, and these organizations pass on changing consumer and market requirements to plant and machine makers. Overall project runtimes should be shorter, and complex plant designs should be customizable.

What Does the Future Hold for Digital Engineering?

As a practice, digital engineering is still relatively new and unrecognized. However, this will not be the case shortly with DoD using digital engineering for system acquisitions. As it flourishes, digital engineering approaches outside the DoD would increase efficiency, testing, safety, and the reuse of physical and digital products. Digital Engineering is getting a lot of impetus from both hi-tech and service-led verticals. Future eras of innovation will demand all processes, systems, and functionalities to be smarter, faster, and more interconnected to deal with all challenges. This implies a massive shift towards digital engineering principles & technologies.

Frequently Asked Questions

1. What are the different types of data sources?

Firms use business intelligence to examine data from a variety of data sources. These most frequently get used as examples:

- Databases

- Flat files

- Web services

- Other sources such as RSS feeds.

2. What is Digital Engineering Technology Architecture Framework?

The DETAF is a model Enterprise Architecture Framework (EAF) for

- Architecting

- Designing

- Building

- Testing

- Integrating Digital Twins that are indistinguishable from their Physical Twins

DETAF’s architecture backbone is the 6D System M-Model Enterprise Architecture Framework for Agile MBSE. This system supports the following key Digital Engineering technologies: Massive Mathematical & Dynamic ModSim, AI & ML, 3D CAD & Printing, VR & AR (AR).

3. How is Digital Engineering related to DevSecOps?

DevSecOps integrates software development, security, and delivery/operations to shorten the time from the requirement to capability and ensure high software quality.

Like DevSecOps, digital engineering emphasizes the organizational integration of people and processes within a development organization and integration team and the ongoing evolution of artifacts.

Updated: July 18, 2022

Updated: July 18, 2022