Retail businesses face the dual challenge of meeting customer demands and ensuring optimal inventory levels. AI utilizes advanced algorithms and ML to analyze large datasets, providing retailers with accurate, real-time insights into consumer demand. Using AI for demand forecasting, retailers can optimize inventories, save money, and engage more customers.

Why Traditional Forecasting Fails

Traditional retail demand forecasting uses basic statistical models and manual overrides. These methods fail to capture the nonlinear patterns in consumer demand and do not account for external factors like market trends and promotional impacts.

Limitations of Traditional Forecasting Methods

While the conventional models have served businesses well in the last decades, they have significant drawbacks compared to AI-powered demand forecasting tools:

- Inaccuracy: Forecasts based solely on historical sales can be misleading, especially during market volatility or unforeseen events.

- The Lack of Real-Time Information: Traditional methods don’t leverage real-time data, such as current market trends or social media hype, making forecasts outdated.

- Manual Intervention: Over-reliance on human assessments and adjustments can introduce bias and errors, affecting overall forecast accuracy.

Consequences of Poor Forecasting

The implications of inaccurate demand forecasting are far-reaching:

- Overstocking: Excess inventory consumes funds and increases warehousing costs.

- Stockouts: Potential sales are lost, and customers are disappointed because of poor stock.

- Inefficient Supply Chain: Poor forecasting disrupts the entire supply chain, leading to delivery delays and increased operating expenses.

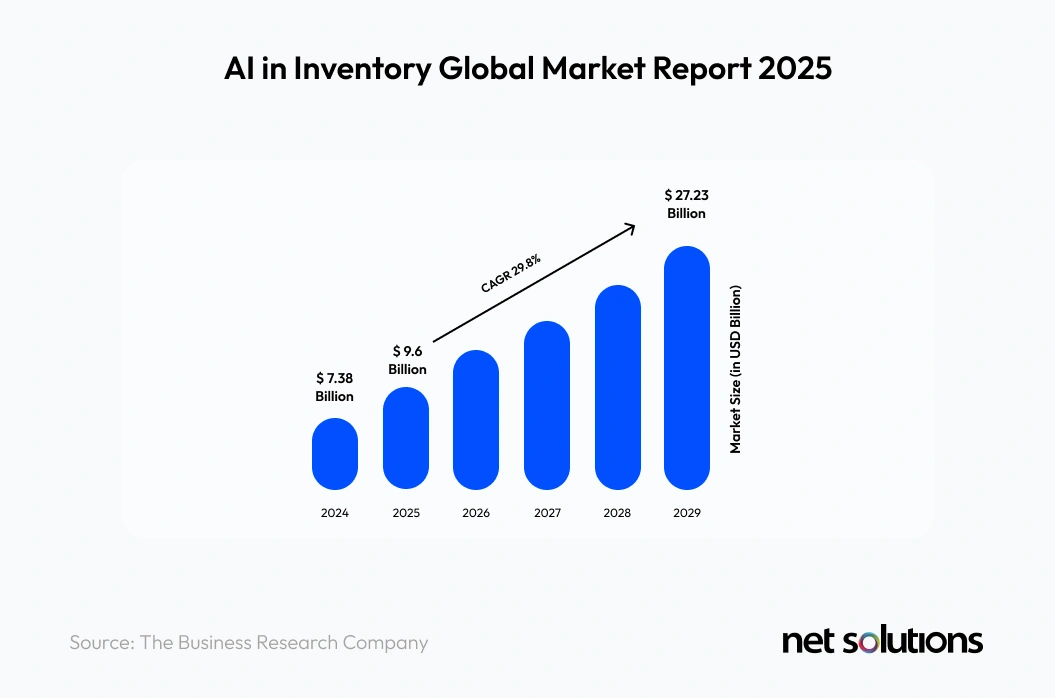

These issues are highly relevant to businesses nowadays. The AI market size in inventory management has grown from $7.38 billion in 2024 to $9.6 billion in 2025 and is projected to reach $27.23 billion in 2029.

The AI Advantage: Revolutionizing Demand Forecasting

AI demand forecasting is based on advanced machine learning algorithms. These algorithms process large data sets to make accurate predictions about consumer demand.

Some of the common algorithms utilized to make predictions are:

- ARIMA: A mathematical model that analyzes past sales to look for trends and seasonality to forecast future demand.

- Random Forest: An ensemble learning method using multiple decision trees to capture complex relationships between variables like price, promotions, etc.

- Gradient Boosting: Builds a series of models that sequentially compensate for the errors of the previous one to enhance prediction.

- LSTM: A recurrent neural network model ideally suited to learn from sequence data and detect long-term dependencies in demand patterns.

These algorithms are trained on historical sales data and external factors such as seasonality, market trends, and promotions to generate precise demand forecasts.

Key Benefits of AI Demand Forecasting

AI is a necessity for businesses to improve supply chains and inventory management.

- Improved Forecast Accuracy: AI-driven models can significantly enhance forecast accuracy. By 2029, 63% of warehouse leaders plan to implement AI to enhance inventory management.

- Cost Reduction: The application of AI in demand forecasting is budget-saving. AI can cut warehousing expenses by 5–10% and administrative costs by 25–40%.

- Boosted Operational Efficiency: AI demand forecasting software reduces the time and effort required for manual analysis. This enhanced effectiveness allows companies to reallocate resources and reduce supply chain complexities.

- Scalability and Flexibility: AI retail demand forecasting models are highly efficient with large data and thus highly scalable for the requirements of any size or complex business. With more data, AI platforms seamlessly adapt to provide accurate forecasts.

Strategies for Predictive Inventory Management with AI

Implementation of AI in inventory management begins with the following steps:

- Identify areas of opportunity, such as stockouts or overstocking.

- Collect and aggregate data from sales, suppliers, and external sources.

- Clean and preprocess data in preparation for use.

- Pick AI techniques such as machine learning for forecasting or optimization.

- Build and train models for demand forecasting, stock optimization, etc.

- Integrate AI into inventory platforms, and educate users on how to act on insights.

- Continuously track and improve model performance.

For a smarter and more reactive inventory process, businesses can apply advanced AI strategies:

1. Real-time Data Integration & Analysis

Traditional forecasting approaches are often reliant on partial or lagged data. AI systems, however, continuously ingest real-time data from diverse sources (sales transactions, web activity, weather, supplier availability, etc).

By integrating these data streams, AI provides retailers a real-time view of inventory and demand. This enables timely decision-making and reduces the likelihood of stockouts or overstocking. A Deloitte research confirms the effectiveness of integrating AI in supply chains.

2. Leveraging ML Models

ML algorithms learn and improve over time from historical data and outcomes. In inventory management, ML can do the following:

- Identify seasonal trends and demand variation.

- Detect anomalies (for example, unexpected sales spikes).

- Adjust reorder points automatically.

3. Scenario Planning & What-If Analysis

AI enables advanced scenario modeling—retailers can build “what-if” scenarios to view the effect that price, promotion, or supply availability alterations would have on demand and inventory.

These simulations allow managers to better plan and mitigate risks before they impact operations.

4. Dynamic Replenishment & Order Optimization

Retail demand forecasting with AI transforms replenishment from a static schedule into a dynamic, responsive process. Below, you can see what AI can do automatically:

- Optimize reorder quantities based on real-time demand.

- Take into account lead times, supplier performance, and holding costs.

- Prevent stockouts without overloading storage space.

5. Personalization & Hyper-localization

AI can also customize decisions to match local demand patterns. Predictive models can split store or neighborhood-level inventory requirements, considering local events, demographics, and consumer preferences.

Case Studies: Demand Forecasting in the Retail Industry

Many well-known companies have already implemented AI in their inventory management operations. You’ve definitely heard about these two retailers:

1. Amazon

This global company that sells everything uses AI across its vast logistics network to improve demand forecasting, inventory management, and warehouse automation. AI-driven robots navigate fulfillment centers, optimize picking routes, and speed up operations.

Analysts suggest that Amazon’s advancements in AI and robotics will lead to annual cost savings of up to $16 billion by 2032.

2. Zara

This famous brand employs AI to forecast fashion demand, allocate inventory to stores, and replenish dynamically. The system maintains the appropriate merchandise in the appropriate locations by analyzing sales, weather, and trends. AI also tracks future fashion trends based on customer behavior and social media.

Implementing AI-powered inventory management has decreased holding costs by 15% and enhanced Zara’s stock turnover.

Conclusion

AI is a modern tool for enhancing demand forecasting. Retailers implementing demand forecasting AI now will be quicker than competitors, more profitable, and better equipped to predict future market shifts.

Contact us if you need high-quality AI development services to enhance demand forecasting and inventory management. At Net Solutions, we build AI software to help your company run smoothly and smarter.

FAQs

What is generative AI for forecasting demand?

Generative AI can predict demand patterns using simulated data, create text-based analyses, and formulate adaptive planning strategies, which is crucial for unpredictable markets.

How can AI predict market trends?

AI for forecasting processes vast collections of information—like online behavior, economic indicators, and competitive trends—to detect emerging trends and forecast how they might affect demand.

What are the advantages of using AI in inventory management?

These are the greater precision in demand forecasting, reduced instances of stockouts and overstocking, smarter and more efficient replenishment, and lower carrying costs.