Imagine walking into a retail store and instantly knowing which products are on the shelves, which brands are most visible, and where there are empty spots that need to be filled. Traditionally, store managers or field staff would physically check every aisle, making notes and taking photos. This is time-consuming, prone to human error, and doesn’t scale well, especially for large retail chains.

While working on a recent project for one of our clients, we wanted to make this process smarter, faster, and far more accurate. That’s why we developed a computer vision–powered retail shelf monitoring system that can automatically “see” and understand retail shelves, just like a human eye would, only faster, more consistent, and without fatigue.

What Our System Can Do

Our solution isn’t just another barcode scanner or stock management tool; it’s a retail technology solution built on visual intelligence that understands shelves visually. It can:

- Recognize products and brands in store shelves with up to 95% accuracy.

- Detects empty spaces (gaps) where stock is missing, reducing out-of-stock situations by over 90%.

- Identify product placement even without a predefined shelf plan (no planogram needed).

- Map products to specific shelf rows to improve brand visibility strategies with smart shelves.

For example, if a customer walks into a store and a popular snack is missing from its usual shelf row, our system can instantly flag the empty space, helping staff restock within minutes instead of hours, preventing potential sales loss.

How We Built It

While the technology behind the scenes is complex, the idea is simple: train the system to “see” like a human and “remember” like a supercharged librarian.

Step 1: Teaching the System to See Products and Gaps

We started by training a model to detect two things:

- Products

- Gaps (empty shelf spaces)

We didn’t have millions of images. In fact, we used just 250 labeled smart shelf technology images to get the model started. With the right data labeling and iterative training, the model quickly reached over 90% detection accuracy for both products and gaps in controlled environments.

Step 2: Teaching the System to Recognize Specific Products

Seeing a “product” is one thing, but knowing exactly which product it is is another challenge. We used an OpenAI model to generate embeddings – think of them as “digital fingerprints” of each product image in our catalog. These embeddings are stored in a vector database for rapid lookup.

When a new shelf photo is received, the system compares cropped product images to our stored embeddings to find the closest match, achieving over 90% accurate product identification in real-world store images. This makes inventory management smarter and more efficient for large retailers.

Step 3: Teaching the System to Recognize Shelf Rows

Knowing which products are present is useful, but retailers also need to know where they are placed.

We trained a second model to detect entire shelves in an image. The system numbers the shelves from bottom to top, enabling precise mapping, such as “Brand A chips are on Shelf 3.”

Importantly, since the position of products within a shelf can change frequently, we do not pinpoint the exact left/right position. Instead, we focus on identifying gaps available for restocking, an essential step in shelf monitoring for modern retail chains.

How It Works in Action

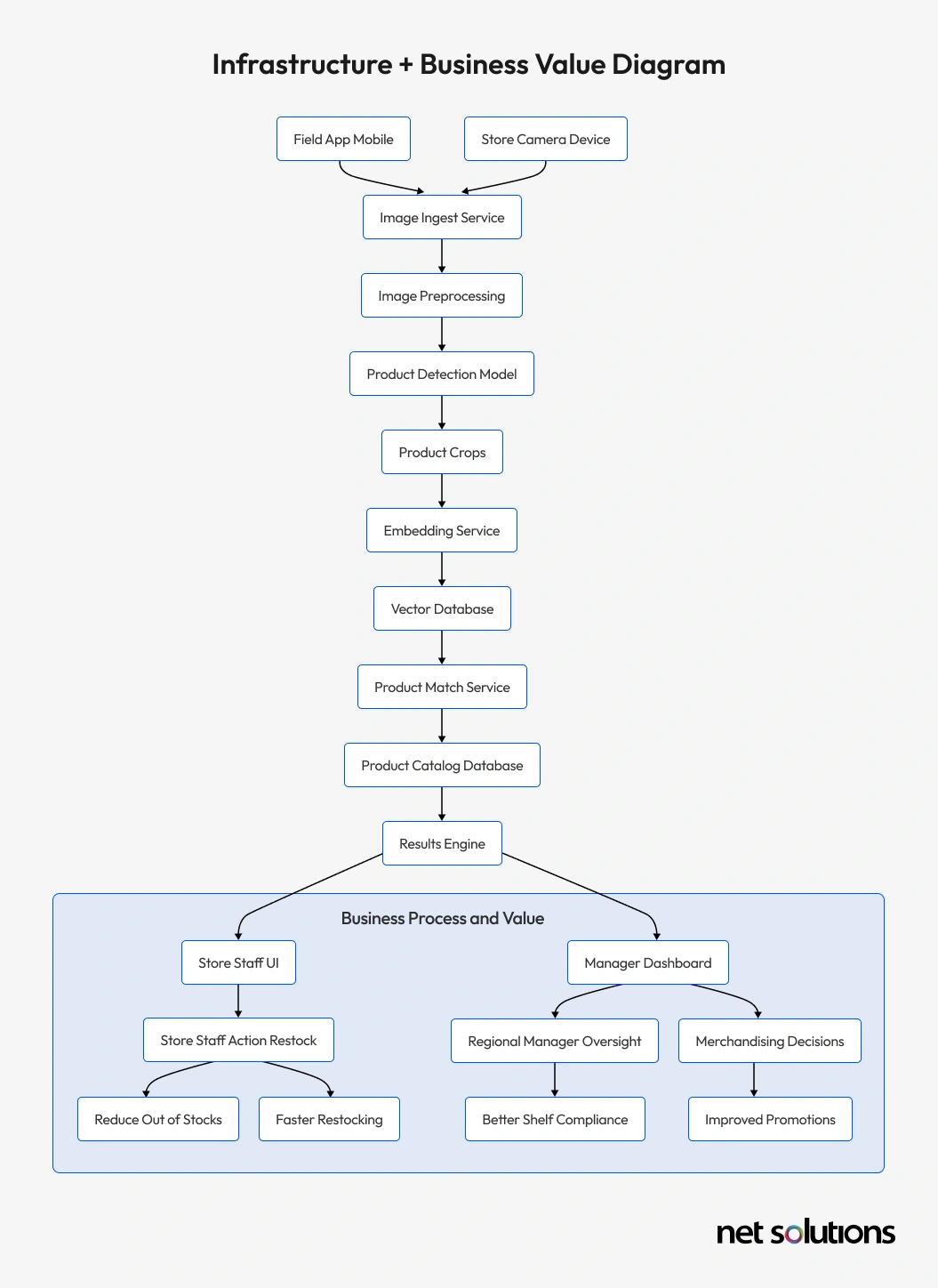

Here’s the end-to-end process when we feed the system a photo of a retail shelf:

- Detect Products and Gaps: The first model identifies all products and empty spots, drawing bounding boxes around them.

- Crop Product Images: Each detected product is cut out from the main image for individual analysis.

- Match Products to Catalog: The cropped image is converted into embeddings and compared against our product database in a vector database to find the best match.

- Retrieve Product Details: Using the matched metadata, the system fetches product name, brand, SKU, and other details.

- Detect Shelf Rows: The second model identifies each shelf in the image and assigns a number from bottom to top.

- Map Products to Shelves: By comparing coordinates, the system determines exactly which shelf each product is on and flags shelves with available space.

This process takes less than 5 seconds per image, enabling near real-time retail automation at scale.

Why This Matters for Retailers

The benefits go beyond just “knowing what’s on the shelf.” Retailers can:

- Reduce lost sales by detecting empty spaces up to 70% faster than manual checks.

- Optimize brand placement to increase product visibility by an average of 20%.

- Automate inventory management audits, freeing up staff to focus on more customer-centric tasks.

- Conduct remote smart shelves in retail compliance checks for over 50 stores daily, eliminating the need for physical visits.

The Bigger Picture

This is not just about technology; it’s about bridging the gap between the physical retail world and digital intelligence. The ability to see shelves, recognize brands, and detect gaps in real time means better stock availability, happier customers, and increased sales.

As retail competition grows and e-commerce sets new expectations, tools like smart shelves and retail shelf monitoring will become essential. Not just a “nice to have,” but a key competitive differentiator. We envision a future where retail automation integrates seamlessly into omnichannel strategies, driving retail into a fully automated, data-driven era.